Dew Point Meters

Dew point meters measure the temperature at which water vapor condenses, a critical parameter in many industrial processes. They help prevent moisture-related issues such as corrosion and product contamination, and by providing real-time data, they support operational efficiency and consistent product quality. Common industries using dew point meters include compressed air systems, HVAC, pharmaceuticals, and food processing.

Key Components in Dew Point Measurement Instruments

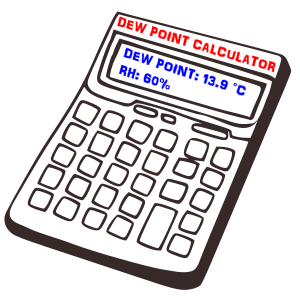

Dew point instruments include three primary components. Each plays a distinct role in detecting moisture, transmitting data, and presenting readings to operators or control systems.

- Sensors: Every sensor inludes a sensing element. These devices detect humidity or moisture levels using various technologies. Sensors are designed to deliver precise measurements over a broad range of conditions, ensuring reliability in diverse industrial settings.

- Transmitters: Transmitters receive signals from the sensors and convert them into standardized outputs, such as 4–20 mA or digital protocols. This enables seamless integration with process control systems, data loggers, or supervisory control and data acquisition (SCADA) networks.

- Meters: Sometimes called the “front end,” meters display the measured dew point in real time and may include features like alarms, data storage, and diagnostic tools. Portable units allow for spot checks, while inline meters provide continuous, automated monitoring.

Types of Sensors

There are are two common types of sensor elements used in dew point measurement, each offering unique advantages depending on the application and required accuracy:

-

Capacitive Sensors:

- Measure changes in capacitance caused by varying moisture levels.

- Offer a good balance between cost, durability, and accuracy.

- Commonly used in industrial applications due to their reliability.

-

Chilled Mirror Sensors:

- Cool a reflective surface until condensation forms to determine the dew point.

- Since they use first priciple mesurement, they provide highly accurate, direct physical measurements.

- In a dusty environment, they can be easily cleaned to maintain accuracy.

Key Attributes to Consider When Selecting a Dew Point Meter

Before purchasing a dew point meter, it’s important to evaluate certain attributes that will influence performance, maintenance, and integration with existing systems:

-

Measurement Range and Accuracy:

- Check the specified range (e.g., -100 °C to +20 °C) to ensure it covers your operational requirements.

- Consider the acceptable margin of error and resolution for your process.

-

Response Time:

- Fast-responding sensors are critical for processes that experience quick humidity changes.

- Slower response may be acceptable in stable environments or where real-time control is less critical.

-

Environmental and Certification Requirements:

- Ensure the device can withstand the operating temperature, pressure, and humidity range in your facility.

- Check for certifications like ATEX or IECEx if working in hazardous or explosive environments.

-

Connectivity and Integration:

- Determine if you need analog outputs (4–20 mA) or digital protocols (Modbus, Ethernet) for data transmission.

- Consider wireless or cloud-based options for remote monitoring and data logging.

-

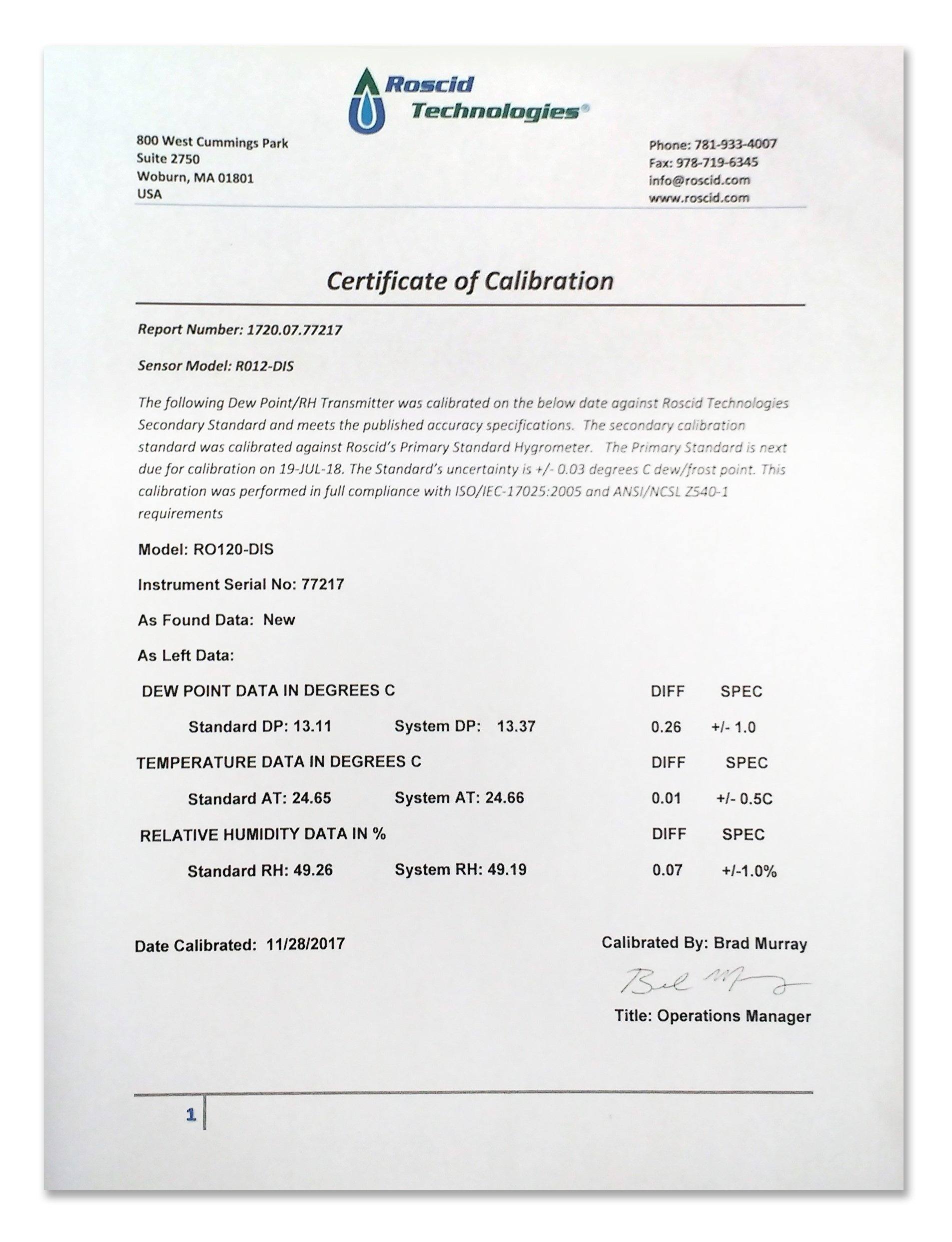

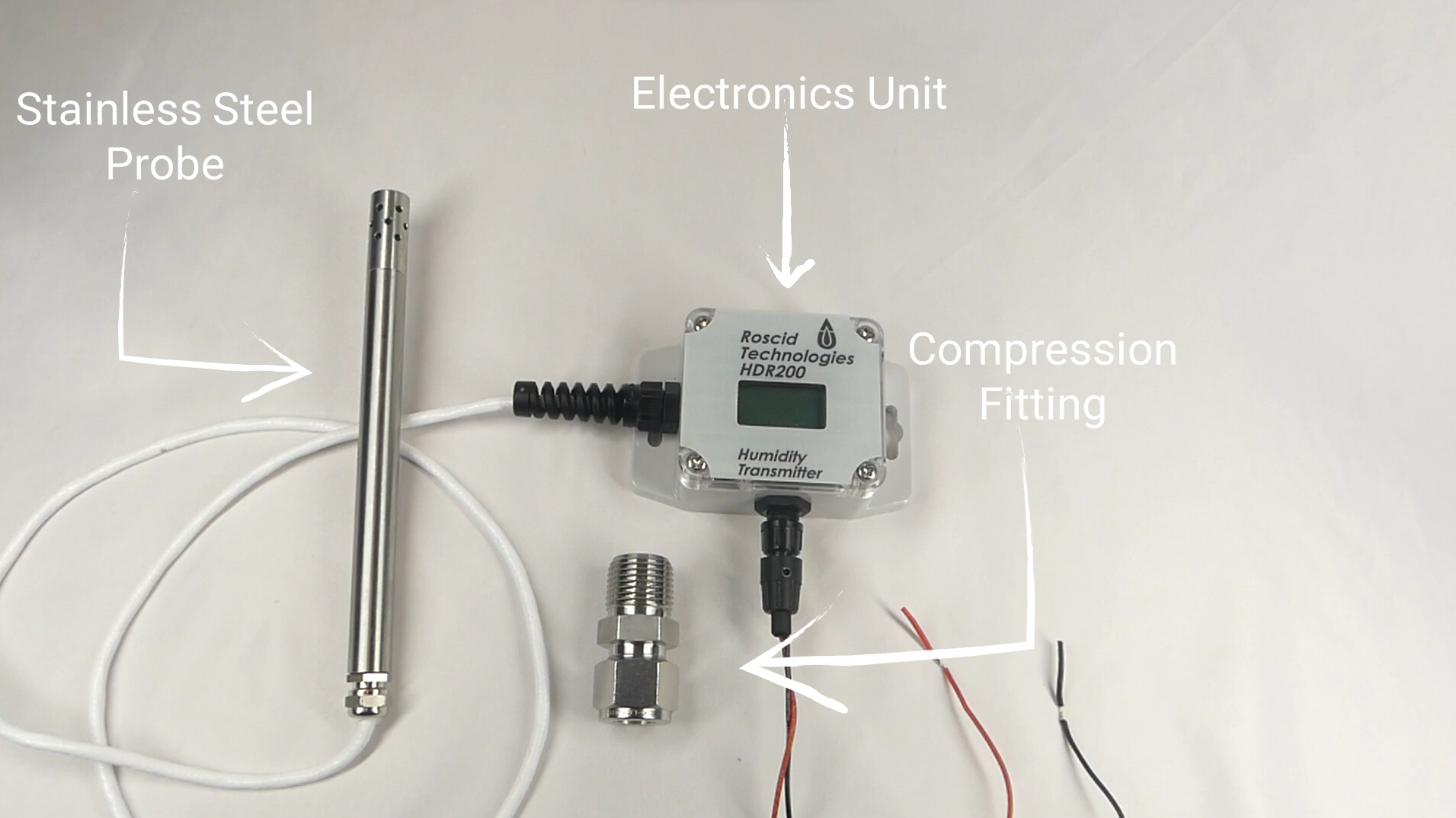

Maintenance and Calibration:

- Chilled mirror sensors typically need more regular cleaning than capacitive or polymer sensors.

- Look for features like auto-calibration or built-in diagnostics that simplify upkeep.

-

Physical Design and Mounting:

- Determine whether you need an inline meter for continuous readings or a portable unit for spot checks.

- Assess the housing (NEMA or IP ratings) to ensure durability in harsh conditions.

-

Cost and ROI:

- Consider total cost of ownership, including initial purchase, installation, and ongoing maintenance.

- Balance the need for high-end features against the projected return on investment through improved process control and reduced downtime.