Industrial furnaces, kilns, and heat-treat ovens rely on accurate temperature monitoring and tight PID control to achieve repeatable cycles, prevent scrap, and satisfy auditors. Robust instrumentation also supports compliance with AMS 2750, CQI-9, ISO 9001, and other quality systems while helping operations reduce energy costs and downtime.

IOThrifty offers a full range of thermocouple probes, controllers, and data loggers. The bundle below highlights three of our most trusted components; contact our applications team with your exact temperature range, atmosphere, and channel count so we can recommend the best fit for your oven, furnace, or kiln.

Data Logging and Control Solutions for Industrial Furnaces

The rugged TJIN K-type thermocouple probe (Inconel sheath, 12 in × 1⁄8 in, 900 °C rating) delivers reliable sensing in oxidizing or reducing atmospheres common to heat-treat and ceramic processes. Wire it to the N20K48 modular PID controller, whose auto-tune algorithm and up to 20 ramp-soak programs keep soak temperatures and ramp rates within spec. Expansion modules add extra relays, analog outputs, or Wi-Fi/RS-485 Modbus connectivity for SCADA integration.

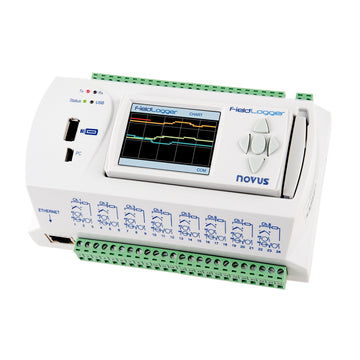

Process values can then be streamed to the FieldLogger data logger, which captures 8 universal inputs at up to 1 000 Hz with 24-bit resolution, buffers 512 k readings, and offers Ethernet, USB, and optional cloud upload for remote dashboards and traceable reports. The result is a turnkey sensor-to-cloud path that supports multi-zone furnaces, facilitates SAT/TUS studies, and provides electronic records auditors expect during AMS 2750 or CQI-9 reviews.

Need different sheath alloys, probe lengths, or additional control loops? IOThrifty stocks dozens of variants—reach out and we’ll tailor a bundle to your exact firing profile and compliance needs.

Need Expert Guidance?

Our application engineers are happy to help you choose the right hardware or build a custom bundle.

Contact Us